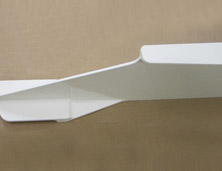

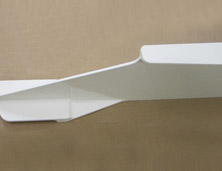

Custom CNC Vertical Milling of an Extruded Aluminum Component for the Aerospace Industry

An aerospace company approached Aljo-Gefa Precision Manufacturing LLC. to fabricate extruded aluminum components which were to be used within an aerospace application. Each component measured between 56" to 86" in length, 2.5" wide, and 4" high, and required vertical milling and profiling. The components required anodizing, priming and painting as well as special packaging. An aerospace company approached Aljo-Gefa Precision Manufacturing LLC. to fabricate extruded aluminum components which were to be used within an aerospace application. Each component measured between 56" to 86" in length, 2.5" wide, and 4" high, and required vertical milling and profiling. The components required anodizing, priming and painting as well as special packaging.

The customer supplied a 2D CAD drawing from which the Aljo Gefa team created the tooling and programmed the CNC vertical milling process. The components met specific tolerances of ±0.015", which was verified on our CMM and manual measuring equipment. The final extruded aluminum aircraft components were specially packaged and shipped, 32 every month, to the customer's location. To learn more about this project or what Aljo Gefa can do for you, see the table below or contact us directly.

Highlights of this Vertical Milling Component Project

| Product Description |

This aluminum extrusion is used within an aerospace application. |

| Capabilities Applied/Processes |

Primary:

Custom Fixture

- Fixture used to Straighten out

Twisted Extrusion Vertical Milling

|

Secondary:

Anodizing

Priming & Painting

Special Packaging | |

| Overall Part Dimensions |

Length: 56" to 86"

Width: 2.5" |

Height: 4" | |

| Tightest Tolerances |

±.015" |

| Material Used |

Aluminum Extrusion |

| Material Finish |

Anodized

Primed & Painted |

| In process testing/inspection performed |

Dimensional Inspection

|

| Industry for Use |

Aerospace |

| Volume |

32 Per Month |

| Delivery/Turnaround Time |

14 to 16 Weeks |

| Delivery Location |

Florida |

| Standards Met |

Customer supplied print, 2D CAD Drawing |

| Product Name |

Extruded Aluminum Aerospace Component |

Back to Top |

Print This Page

Print This Page

An aerospace company approached Aljo-Gefa Precision Manufacturing LLC. to fabricate extruded aluminum components which were to be used within an aerospace application. Each component measured between 56" to 86" in length, 2.5" wide, and 4" high, and required vertical milling and profiling. The components required anodizing, priming and painting as well as special packaging.

An aerospace company approached Aljo-Gefa Precision Manufacturing LLC. to fabricate extruded aluminum components which were to be used within an aerospace application. Each component measured between 56" to 86" in length, 2.5" wide, and 4" high, and required vertical milling and profiling. The components required anodizing, priming and painting as well as special packaging.